NCB500A Automatic Perfect Binding Machine

NCB500A Automatic Perfect Binding Machine

Adopts the whole new generation of intelligential digital control system and bussing technique and the control system has high operation accuracy, speed and reliability, convenient maintenance.

Touch color screen contains texts and figures, spine milling depth, amount of spine glue and side glue, creasing position and depth, glue stop position, flat back and round back can be set and adjusted easily.

Operation record and ergonomics statistics is provided. Put the book block in the clamp, the thickness of the book block will be gauged automatically, and the positioning and adjusting of all the stations will be finished immediately according to the thickness of the book block, the length and thickness of the spine glue and side glue will be controlled and adjusted automatically.

The unique double rail structure ensures the running smoother, updraft paper feed avoids the scratching on the surface of the printed covers.

Easy operation allows one single operator accomplish the whole productive process: put book blocks in the carriage clamp, feed the covers automatically, milling the spine, apply the spine glue and side glue, clamp the spine and collect finished books.

It is intelligential perfect binder for multi-species, short to medium run and digital print finishing jobs.

|

Control system The whole new generation of intelligential digital control system adopts programmable logic technology to configurate hardware by software. Adopts bussing technique, increase operational precision, speed and reliability. |

|

Colorful touch screen Accomplish the operating mode and function set by texts and figures in the 10 inches colorful touch screen. |

|

Book block thickness gauge Put book block in the carriage, the thickness of the book block will be gauged automatically, and the adjusting of all the processes will be finished accordingly in the same time. Different sizes of book block can be quick switched. |

|

Cover paper auto feed Air-aspiration type auto feed, effectively prevent scratching on the surface of printed paper. Feed table goes up and down according to the thickness of the paper pile. Max. paper pile height is 70mm. |

|

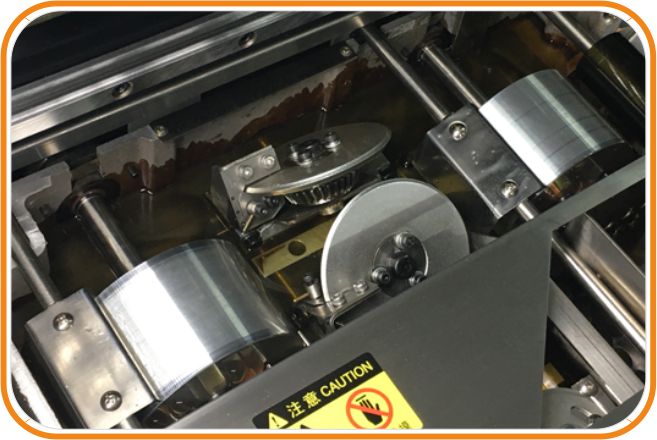

Milling & cutting device This device includes milling, cutting and scraps of paper brushing functions, opening width of milling cutter protect board adjusts the opening width automatically. Turn on / off the milling & cutting function by switch lever. |

|

|

Glue system |

|

|

Cover creasing |

|

Double rail structure The double rail structure ensures the stable running of book block carriage. The book block carriage is integral cast aluminum. |

|

Infrared detection device Put book block in the carriage, machine starts to automatic running after operator's hands leave the detection area. |

|

Auto book collect device Deliver the bound books to book collect device automatically. Warning after the book collect device is full. Built in a Long cover book collect plate. |

NCB500A Automatic Perfect Binding Machine

Adopts the whole new generation of intelligential digital control system and bussing technique and the control system has high operation accuracy, speed and reliability, convenient maintenance.

Touch color screen contains texts and figures, spine milling depth, amount of spine glue and side glue, creasing position and depth, glue stop position, flat back and round back can be set and adjusted easily.

Operation record and ergonomics statistics is provided. Put the book block in the clamp, the thickness of the book block will be gauged automatically, and the positioning and adjusting of all the stations will be finished immediately according to the thickness of the book block, the length and thickness of the spine glue and side glue will be controlled and adjusted automatically.

The unique double rail structure ensures the running smoother, updraft paper feed avoids the scratching on the surface of the printed covers.

Easy operation allows one single operator accomplish the whole productive process: put book blocks in the carriage clamp, feed the covers automatically, milling the spine, apply the spine glue and side glue, clamp the spine and collect finished books.

It is intelligential perfect binder for multi-species, short to medium run and digital print finishing jobs.

|

Control system The whole new generation of intelligential digital control system adopts programmable logic technology to configurate hardware by software. Adopts bussing technique, increase operational precision, speed and reliability. |

|

Colorful touch screen Accomplish the operating mode and function set by texts and figures in the 10 inches colorful touch screen. |

|

Book block thickness gauge Put book block in the carriage, the thickness of the book block will be gauged automatically, and the adjusting of all the processes will be finished accordingly in the same time. Different sizes of book block can be quick switched. |

|

Cover paper auto feed Air-aspiration type auto feed, effectively prevent scratching on the surface of printed paper. Feed table goes up and down according to the thickness of the paper pile. Max. paper pile height is 70mm. |

|

Milling & cutting device This device includes milling, cutting and scraps of paper brushing functions, opening width of milling cutter protect board adjusts the opening width automatically. Turn on / off the milling & cutting function by switch lever. |

|

|

Glue system |

|

|

Cover creasing |

|

Double rail structure The double rail structure ensures the stable running of book block carriage. The book block carriage is integral cast aluminum. |

|

Infrared detection device Put book block in the carriage, machine starts to automatic running after operator's hands leave the detection area. |

|

Auto book collect device Deliver the bound books to book collect device automatically. Warning after the book collect device is full. Built in a Long cover book collect plate. |

|

|

Max. binding size |

320x235mm |

Min. binding size |

135x105mm |

|

Max. binding thickness |

50mm |

Max. paper size |

660x360mm |

|

Max. paper pile height |

70mm |

Binding capability |

Single sheet – 2 fold sheet |

|

Milling cutter |

Disk cutter & small milling cutter |

Milling cutter protector |

Automatic closing |

|

Glue mode |

Spine glue & side glue |

Adhesive melting time |

About 35 minutes |

|

Mechanical speed |

500 books/hour |

Power supply |

380V |

|

Machine weight |

940kg |

Machine dimensions |

2460x940x1520mm |

|

※ Reserve the right to change the parameters without prior notice. |

|||

|

|

Beijing HengYin Machinery Manufacturing Co., Ltd.

京公网安备 11010902000849号

京ICP备06046311号-3

Powered by 300.cn

京公网安备 11010902000849号

京ICP备06046311号-3

Powered by 300.cn

010-58895877

010-58895877